The rhythmic tick-tock of a mechanical clock is more than just a way to tell time; it's a connection to history, a testament to intricate engineering, and often a cherished heirloom. But what happens when that rhythm falters? Understanding the world of mechanical clock repair components is key to restoring these fascinating machines to their former glory. This article delves into the essential aspects of these components, from their historical significance to practical advice on sourcing and utilizing them.

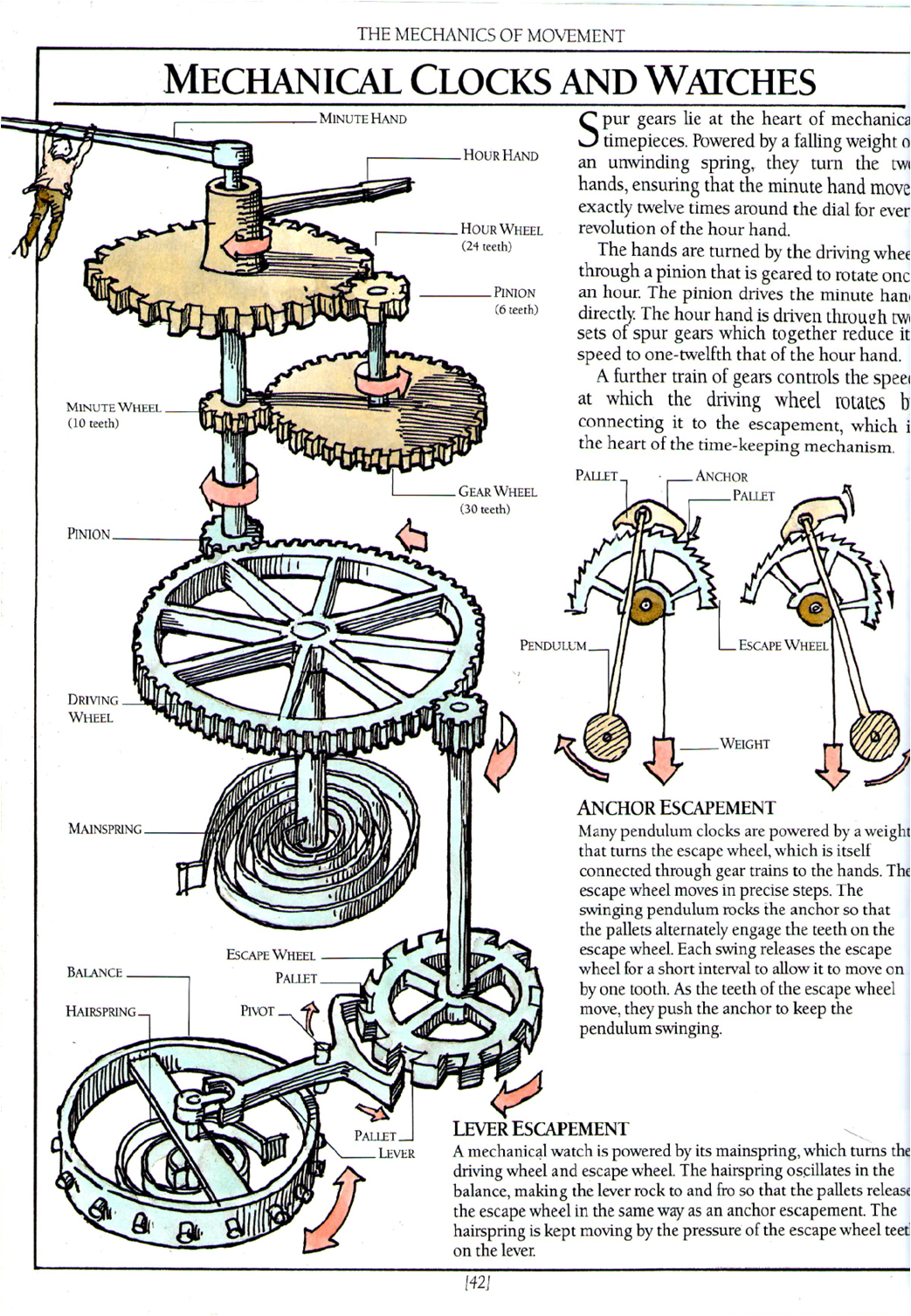

Imagine the intricate dance of gears, springs, and levers within a clock's casing. Each component plays a vital role, working in harmony to maintain accurate timekeeping. From the smallest pinion to the largest mainspring, these components are the lifeblood of any mechanical clock. Whether you're a seasoned horologist or a curious beginner, understanding the function and maintenance of these parts is crucial for anyone who appreciates the art of mechanical timekeeping.

The history of mechanical clock repair components is intertwined with the evolution of clockmaking itself. Early clocks relied on simple verge escapements and rudimentary gear trains. As technology advanced, so did the complexity and precision of these components. The development of the pendulum escapement by Christiaan Huygens in the 17th century was a major leap forward, leading to more accurate timekeeping and the demand for higher quality components. This evolution continued, resulting in the sophisticated mechanisms we see in antique and modern mechanical clocks today.

One of the main challenges in mechanical clock repair is sourcing the correct components. Finding replacements for worn or broken parts can be difficult, especially for older or less common clocks. Understanding the specific nomenclature and measurements is essential for accurate identification and ordering. Luckily, a growing number of online resources and specialized suppliers cater to the needs of clock enthusiasts and professionals, making it easier to find the necessary components for maintaining these intricate timepieces. Resources such as online forums and communities can also offer valuable advice and guidance.

Maintaining a mechanical clock involves more than just winding it regularly. Regular cleaning, lubrication, and inspection are essential for preventing wear and tear on the delicate components. Understanding how each component interacts with the others is crucial for diagnosing problems and performing effective repairs. For instance, a worn escapement wheel can cause erratic timekeeping, while a broken mainspring will prevent the clock from running altogether. By familiarizing yourself with the workings of your clock, you can identify potential issues early on and take steps to prevent costly repairs.

Benefits of quality mechanical clock repair components include extended clock lifespan, improved accuracy, and preservation of the clock's historical value. Using appropriate cleaning solutions and lubricants is also vital for maintaining the longevity of the components.

A simple action plan for maintaining a mechanical clock involves regular inspection, cleaning, and lubrication. You should also address any issues promptly by consulting a qualified clock repairer if necessary.

Advantages and Disadvantages of Using Original vs. Replica Parts

| Feature | Original Parts | Replica Parts |

|---|---|---|

| Authenticity | Preserves historical integrity | May compromise historical value |

| Cost | Often expensive and difficult to find | Generally more affordable and readily available |

| Quality | High quality, long-lasting | Variable quality, may not last as long |

Best Practices for Implementing Mechanical Clock Repair Components:

1. Use appropriate tools.

2. Handle parts with care.

3. Clean parts thoroughly before reassembly.

4. Lubricate moving parts correctly.

5. Test the clock after repair.

Frequently Asked Questions:

1. Where can I find mechanical clock repair parts? Answer: Specialized suppliers, online retailers, and auction sites.

2. How do I identify the correct parts for my clock? Answer: Consult clock repair manuals or seek expert advice.

3. How often should I clean and lubricate my clock? Answer: Generally every 2-5 years, depending on the clock and environment.

4. What type of lubricant should I use? Answer: Specialized clock oil designed for delicate mechanisms.

5. Can I repair my clock myself? Answer: Simple repairs can be done by enthusiasts, but complex issues require professional expertise.

6. What are the common signs of a malfunctioning clock? Answer: Inaccurate timekeeping, unusual noises, or complete stoppage.

7. How much does clock repair typically cost? Answer: Varies depending on the complexity of the repair and the experience of the repairer.

8. How can I prevent damage to my mechanical clock? Answer: Regular maintenance, proper handling, and avoiding extreme temperatures or humidity.

Tips and Tricks: Keep a detailed record of any repairs performed, including the parts used and the date of service. This will be helpful for future maintenance and can also enhance the value of the clock. Invest in a good set of clock repair tools to make the process easier and more efficient.

In conclusion, the world of mechanical clock repair components is a fascinating blend of history, engineering, and artistry. Whether you're a seasoned collector or simply appreciate the craftsmanship of these intricate machines, understanding the importance of proper maintenance and the availability of quality repair components is essential for keeping your timepiece ticking for generations to come. By taking the time to learn about these components and following best practices for repair and maintenance, you can ensure that your mechanical clock continues to function accurately and retain its value. Embrace the opportunity to learn more about the inner workings of these timeless mechanisms and contribute to the preservation of horological history. Don't let your clock fall silent—invest in its care and enjoy the enduring charm of mechanical timekeeping.

Navigating the maze dui legal counsel in new orleans

Electrifying your vessel mastering the art of boat switch panels

Understanding judge quinones part rules