Ready to hit the water? Installing an outboard motor can seem daunting, but with the right guidance, it's a manageable project even for DIY enthusiasts. This comprehensive guide will walk you through the outboard motor installation process, offering practical advice and essential tips to ensure a smooth and successful setup.

Choosing the right outboard motor is the first crucial step. Factors like boat size, intended use, and budget play a significant role. Research different brands, horsepower ratings, and features to find the perfect match for your vessel. Remember, a properly matched motor ensures optimal performance and fuel efficiency.

Once you've selected your motor, gather the necessary tools and materials. These typically include wrenches, sockets, screwdrivers, mounting bolts, sealant, and a fuel line. Having everything on hand before starting the installation process will save you time and frustration.

The history of outboard motors is a testament to innovation. From the early, rudimentary designs to the powerful, technologically advanced engines of today, outboard motors have revolutionized boating. Understanding the evolution of these engines provides context for the importance of proper installation.

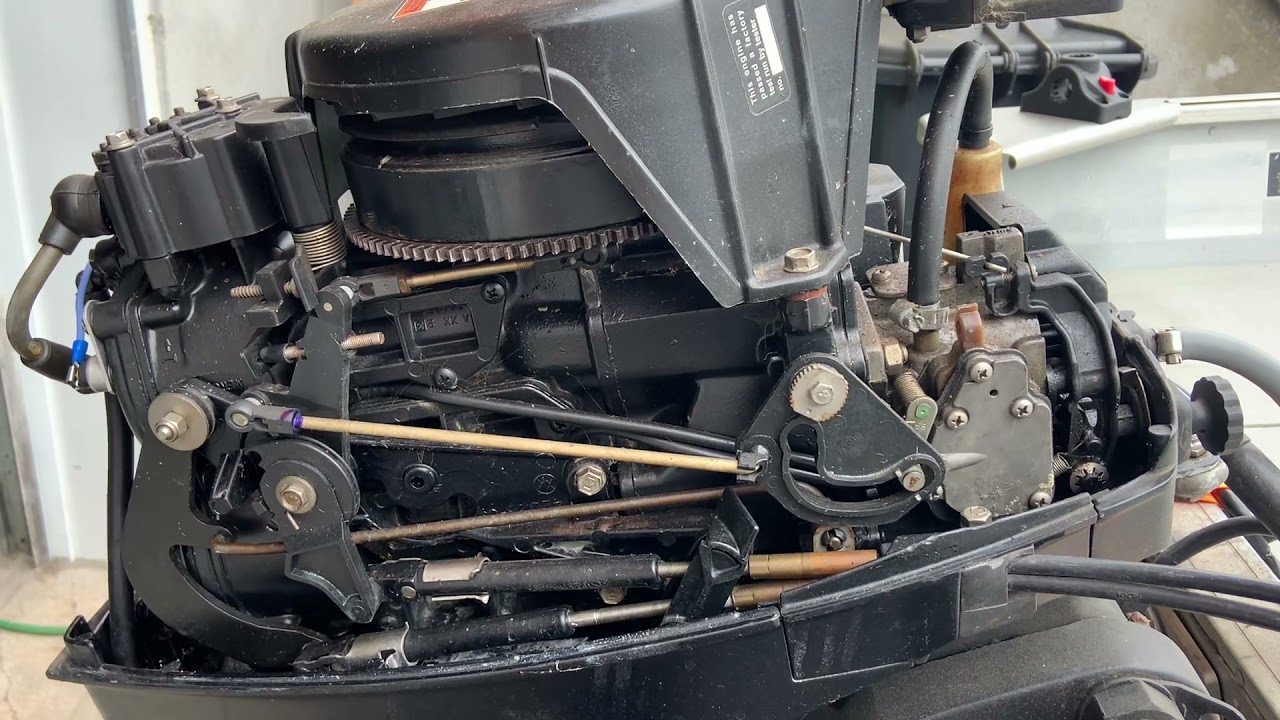

Correct outboard motor mounting is essential for safety and performance. Securely attaching the motor to the transom is paramount. Incorrect mounting can lead to vibration, damage to the boat, and even motor detachment – a dangerous situation. This guide will detail the precise steps for secure mounting, ensuring your motor stays put, no matter the conditions.

Before mounting, carefully inspect the transom for any damage. The transom must be strong enough to support the weight and thrust of the outboard. Repair any damage before proceeding with the installation.

Connecting the fuel line and controls is a critical part of the process. Use the correct type of fuel line and ensure all connections are secure and leak-free. Properly connect the throttle and shift cables for smooth and responsive control of the motor.

Benefits of proper outboard motor installation:

1. Enhanced Performance: A correctly installed motor maximizes power and efficiency, providing optimal speed and fuel economy.

2. Improved Safety: Secure mounting and proper connections minimize the risk of accidents and ensure safe operation.

3. Increased Longevity: Correct installation reduces wear and tear on the motor, extending its lifespan.

Outboard Motor Installation Steps:

1. Prepare the Transom: Inspect and reinforce if necessary.

2. Position the Motor: Align it correctly on the transom.

3. Secure the Mounting Bolts: Tighten them to the manufacturer's specifications.

4. Connect the Fuel Line: Ensure a secure and leak-free connection.

5. Connect the Control Cables: Adjust for proper throttle and shift operation.

Advantages and Disadvantages of DIY Outboard Motor Installation

| Advantages | Disadvantages |

|---|---|

| Cost savings | Potential for errors |

| Sense of accomplishment | Risk of damage to equipment |

Best Practices:

1. Consult your owner's manual for specific instructions.

2. Use marine-grade sealant to prevent corrosion.

3. Double-check all connections.

4. Test the motor thoroughly after installation.

5. Have a professional inspect the installation if you are unsure.

Frequently Asked Questions:

1. What size outboard motor do I need? (Answer: Depends on boat size and intended use)

2. What tools are required? (Answer: Wrenches, sockets, screwdrivers, etc.)

3. How do I connect the fuel line? (Answer: Securely to the fuel connector)

4. How do I adjust the throttle cable? (Answer: According to the manufacturer's instructions)

5. How do I mount the motor on the transom? (Answer: Use the correct mounting bolts and sealant)

6. What is the proper height for the motor? (Answer: Consult your owner's manual)

7. How do I troubleshoot starting problems? (Answer: Check fuel, spark plugs, and connections)

8. What maintenance is required after installation? (Answer: Regular checks and servicing)

Tips and Tricks:

Use anti-seize lubricant on bolts to prevent corrosion and make future removal easier.

In conclusion, installing an outboard motor is a manageable task with the right preparation and guidance. Following the steps outlined in this guide will help ensure a successful installation, leading to enhanced performance, improved safety, and increased longevity of your outboard motor. Take your time, double-check your work, and don't hesitate to seek professional advice if needed. The open water awaits, and with a properly installed outboard motor, you'll be ready to explore it with confidence and enjoyment. Remember, a well-maintained and correctly installed outboard is key to a safe and enjoyable boating experience. By investing time and effort in proper installation, you are investing in years of trouble-free boating adventures. So gather your tools, consult your manual, and get ready to enjoy the fruits of your labor on the water!

Unraveling the mystery the afton family saga in five nights at freddys

Unleash the power of pediment your sherwin williams color guide

The enduring charm of hello kitty profile pictures