Electricity. It's the lifeblood of our modern world, powering everything from the subtle hum of our refrigerators to the dazzling displays of our smart TVs. But as our power demands grow, so does the need for robust and reliable electrical systems. Enter the 200 amp subpanel – a crucial component for expanding your home's electrical capacity. Choosing the right wire for a 200 amp subpanel installation isn't just a matter of picking a random roll off the shelf; it's about understanding the science of safe and efficient power delivery.

Imagine trying to fill a bathtub with a garden hose versus a firehose. The garden hose works fine for smaller tasks, but for a large volume of water, the firehose is essential. Similarly, undersized wiring for a 200 amp subpanel creates a bottleneck, restricting the flow of electricity and potentially leading to overheating and hazards. Proper wire sizing, based on amperage and distance, is paramount to avoid such issues.

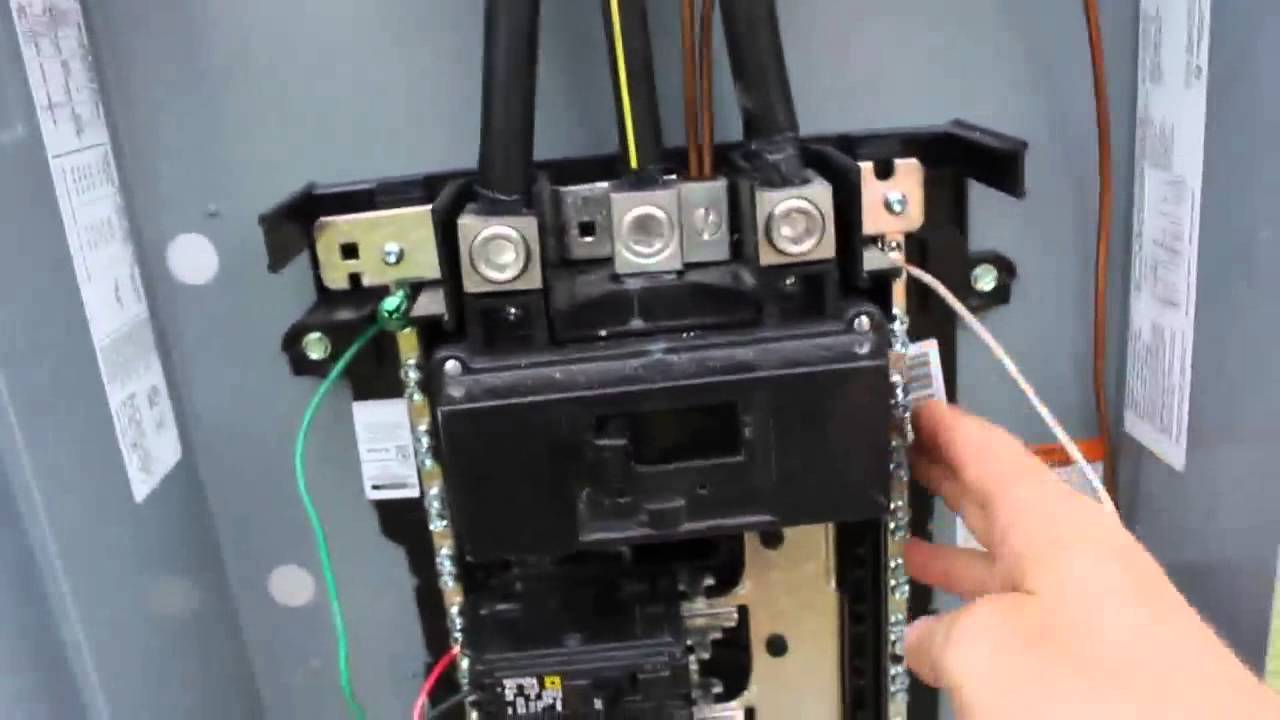

Over the past century, household electricity demands have increased dramatically. From simple lighting and appliances to the energy-hungry devices of today, the need for greater capacity has driven the adoption of subpanels. A 200 amp subpanel provides a dedicated circuit for high-power appliances like workshops, electric vehicle chargers, and additional living spaces. This evolution necessitates meticulous attention to wiring specifications to ensure the system operates safely and effectively.

Selecting the correct wire gauge for your 200 amp subpanel connection is the cornerstone of a safe and functional electrical setup. The "gauge" refers to the wire's thickness – the lower the gauge number, the thicker the wire, and the more current it can safely carry. Using a wire gauge that's too small for the amperage can cause the wire to overheat, potentially leading to fire hazards. This highlights the importance of understanding the relationship between amperage, wire gauge, and distance.

The primary concern with incorrect wiring for a 200 amp subpanel is safety. Overloaded wires generate excessive heat, which can melt insulation, cause short circuits, and even ignite nearby materials. Beyond the immediate danger of fire, inadequate wiring can also lead to voltage drops, causing appliances to malfunction or operate inefficiently. Investing the time to select the correct 200 amp sub panel wire size is an investment in the safety and longevity of your electrical system.

A key aspect of 200 amp subpanel wiring is the use of appropriately rated conductors. These conductors are typically copper or aluminum, each with different ampacity ratings. Copper is more conductive and requires a smaller gauge for the same amperage compared to aluminum. Understanding these differences is crucial when determining the suitable 200 amp subpanel wire size for your specific needs.

Choosing the correct wire for a 200 amp subpanel involves considering the distance between the main panel and the subpanel. Longer runs require thicker wires to compensate for voltage drop. Online calculators and electrician consultations are invaluable resources for determining the precise wire gauge needed for your specific setup.

Advantages and Disadvantages of Different Wire Types

| Wire Type | Advantages | Disadvantages |

|---|---|---|

| Copper | Excellent conductivity, requires smaller gauge | More expensive than aluminum |

| Aluminum | Lighter and less expensive | Requires larger gauge, susceptible to oxidation |

Best Practices for 200 Amp Subpanel Wiring:

1. Consult local electrical codes: Ensure your wiring adheres to local regulations.

2. Use appropriate conduit: Protect the wiring from damage.

3. Secure connections: Tighten all connections to prevent overheating.

4. Label circuits clearly: Facilitate future maintenance and troubleshooting.

5. Ground the subpanel correctly: Essential for safety.

Frequently Asked Questions:

1. What wire size do I need for a 200 amp subpanel? Consult an electrician or online calculator based on distance and load.

2. Can I use aluminum wire for a 200 amp subpanel? Yes, but it requires a larger gauge than copper.

3. What is the importance of grounding? Grounding protects against electrical shocks.

4. How do I calculate voltage drop? Use online calculators or consult an electrician.

5. Can I install a 200 amp subpanel myself? It's recommended to hire a qualified electrician.

6. What type of conduit should I use? Consult local codes for appropriate conduit type.

7. How often should I inspect my subpanel? Regular inspections by a qualified electrician are recommended.

8. What are the signs of a faulty subpanel? Burning smells, flickering lights, and tripped breakers.

In conclusion, selecting the correct wire for your 200 amp subpanel is a crucial aspect of ensuring a safe, efficient, and reliable electrical system. Understanding the relationship between amperage, wire gauge, and distance is paramount. While online resources provide valuable information, consulting with a qualified electrician is always recommended. Properly sized wiring not only protects your home and appliances from potential hazards but also ensures that your electrical system is equipped to handle the demands of modern living. By prioritizing safety and adhering to best practices, you can power your future with confidence, knowing that your 200 amp subpanel installation is built to last. Investing in the right wiring from the start saves you from potential headaches and hazards down the line. Don't underestimate the power of proper wiring - it's the foundation of a robust and reliable electrical system. Consult a professional, follow local codes, and make informed decisions. Your peace of mind is worth the investment.

Unlock savings with the fresh value bessemer weekly ad

Unlocking the beast mk4 jetta front mount intercooler deep dive

Sherwin williams agreeable gray cabinets the ultimate guide