There's a certain satisfaction that comes from breathing new life into a classic. In the automotive world, the 5.3L Vortec engine holds a special place. This workhorse powerplant, known for its reliability and torque, has powered countless trucks and SUVs. But even the most durable engines eventually need some attention. This guide delves into the intricacies of 5.3 Vortec engine rebuilding, exploring the process, benefits, and common pitfalls.

Restoring a 5.3 Vortec isn't just about bolting on new parts. It's about understanding the engine's nuances, appreciating its history, and meticulously crafting a revitalized powerplant. From diagnosing worn components to selecting the right replacement parts, every step requires careful consideration. This comprehensive guide will equip you with the knowledge and resources to embark on your own 5.3 Vortec rebuild journey.

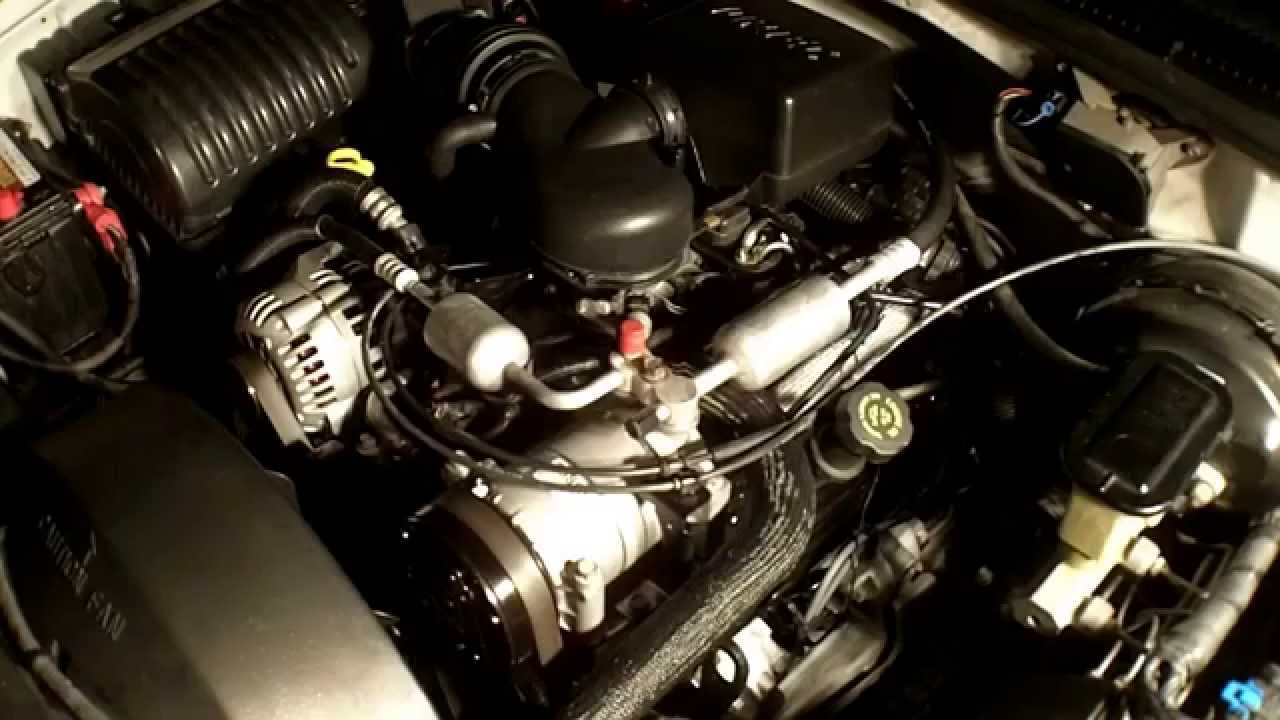

The 5.3L Vortec engine, introduced by General Motors in 1999, became a staple in their truck and SUV lineup. Its popularity stemmed from its robust design, ample power delivery, and relative fuel efficiency. Over the years, different variations of the 5.3 Vortec emerged, each with its own unique characteristics. Understanding these variations is crucial when planning a rebuild, as it dictates the specific parts and procedures required.

A common reason for undertaking a 5.3 Vortec rebuild is excessive oil consumption, often caused by worn piston rings or valve seals. Another frequent issue is a loss of compression, which can indicate damaged pistons or cylinder walls. Addressing these issues through a rebuild not only restores performance but also extends the engine's lifespan.

Rebuilding a 5.3 Vortec involves a meticulous disassembly process, where each component is inspected for wear and tear. This includes everything from the crankshaft and connecting rods to the cylinder heads and valves. Once the inspection is complete, worn parts are replaced with new or refurbished components. The engine is then carefully reassembled, ensuring proper clearances and torque specifications are met.

One of the key benefits of rebuilding a 5.3 Vortec is the significant cost savings compared to buying a new engine. Additionally, a rebuild allows for customization and performance enhancements. You can choose to upgrade certain components, such as the camshaft or intake manifold, to boost horsepower and torque.

Another advantage is the environmental benefit of reusing and refurbishing existing components rather than contributing to the demand for new manufacturing. Finally, a successful rebuild provides the satisfaction of knowing you've breathed new life into a classic engine.

Advantages and Disadvantages of Rebuilding a 5.3 Vortec

| Advantages | Disadvantages |

|---|---|

| Cost-effective compared to a new engine | Time-consuming process |

| Opportunity for performance upgrades | Requires specialized tools and knowledge |

| Environmentally friendly | Potential for unforeseen issues |

Best Practices for Rebuilding a 5.3 Vortec:

1. Use a high-quality rebuild kit: This ensures all necessary components are included and meet the required specifications.

2. Thoroughly clean all engine parts: Removing any debris or contaminants is crucial for proper engine function.

3. Accurately measure clearances: Precise measurements ensure proper fit and prevent premature wear.

4. Use proper torque specifications: This prevents damage to components and ensures proper assembly.

5. Break-in the engine correctly: Following the manufacturer's break-in procedure is essential for engine longevity.

Frequently Asked Questions about Rebuilding a 5.3 Vortec:

1. How much does it cost to rebuild a 5.3 Vortec? Answer: The cost varies depending on the extent of the rebuild and the parts used.

2. How long does it take to rebuild a 5.3 Vortec? Answer: The time required depends on your experience and the complexity of the rebuild.

3. What tools are needed to rebuild a 5.3 Vortec? Answer: A variety of specialized tools are required, including torque wrenches, micrometers, and engine stands.

4. Can I rebuild a 5.3 Vortec myself? Answer: While possible, it's recommended to have prior engine rebuilding experience.

5. What are the common issues with 5.3 Vortecs? Answer: Common issues include oil consumption, lifter noise, and intake manifold gasket leaks.

6. How can I improve the performance of my 5.3 Vortec during a rebuild? Answer: Upgrading the camshaft, intake manifold, and exhaust system can boost performance.

7. Where can I find resources for rebuilding a 5.3 Vortec? Answer: Online forums, repair manuals, and YouTube videos offer valuable information.

8. What are the signs that my 5.3 Vortec needs a rebuild? Answer: Decreased performance, excessive oil consumption, and unusual engine noises can indicate a need for a rebuild.

Tips and Tricks for Rebuilding a 5.3 Vortec:

Organize your parts meticulously during disassembly. Label everything and take plenty of pictures.

In conclusion, rebuilding a 5.3 Vortec engine is a rewarding undertaking that can revitalize your vehicle's performance and extend its lifespan. While it requires careful planning, meticulous execution, and specialized knowledge, the benefits of a successful rebuild far outweigh the challenges. By following best practices, utilizing available resources, and understanding the intricacies of this robust engine, you can transform a worn-out powerplant into a finely tuned machine. This journey of restoration is not just about fixing a motor; it's about reviving a legend, one meticulously crafted component at a time. So, gather your tools, embrace the challenge, and experience the satisfaction of breathing new life into your 5.3 Vortec. Take the first step towards revitalizing your engine – research, plan, and prepare for a rewarding experience.

Englewood florida final farewells obituaries and funeral homes

Ending agreements contract termination letters

John vaughns age and its relevance