Imagine a world where heavy gems and delicate jewels are transported with effortless precision, their movement orchestrated by a hidden force. This is the realm of the gem lift control box, a critical piece of technology in industries ranging from jewelry manufacturing to museum exhibitions. These unsung heroes of material handling provide the brains and brawn behind lifting systems, enabling the safe and efficient movement of precious cargo.

The gem lift control unit, in its essence, is the command center for a lifting mechanism. It houses the electrical components, controls, and logic that dictate the movement of the lift. Think of it as the conductor of an orchestra, coordinating the various parts of the system to work in harmony. Whether it's a small platform lifting a single gemstone for inspection or a large crane hoisting a priceless artifact, the gem lift controller ensures smooth and controlled operation.

While the precise origins of the gem lift control box are difficult to pinpoint, its development is intertwined with the broader evolution of electric motor controls and automation. As industries sought more efficient ways to handle materials, the need for sophisticated lifting systems grew. This demand fueled innovation in control mechanisms, leading to the compact and powerful units we see today.

The importance of the gem lift control box cannot be overstated. It's the critical link between the operator and the lifting mechanism, providing a safe and predictable way to manipulate heavy or delicate items. Without it, the risk of accidents, damage, and inefficiency would be significantly higher. Properly functioning gem lift controllers are essential for maintaining productivity, preserving valuable materials, and ensuring worker safety.

Common issues with gem lift control mechanisms can range from simple electrical faults to more complex software glitches. Overheating, worn-out components, and improper wiring can all contribute to malfunctions. Understanding these potential problems and implementing preventative maintenance is crucial for ensuring the longevity and reliability of the system.

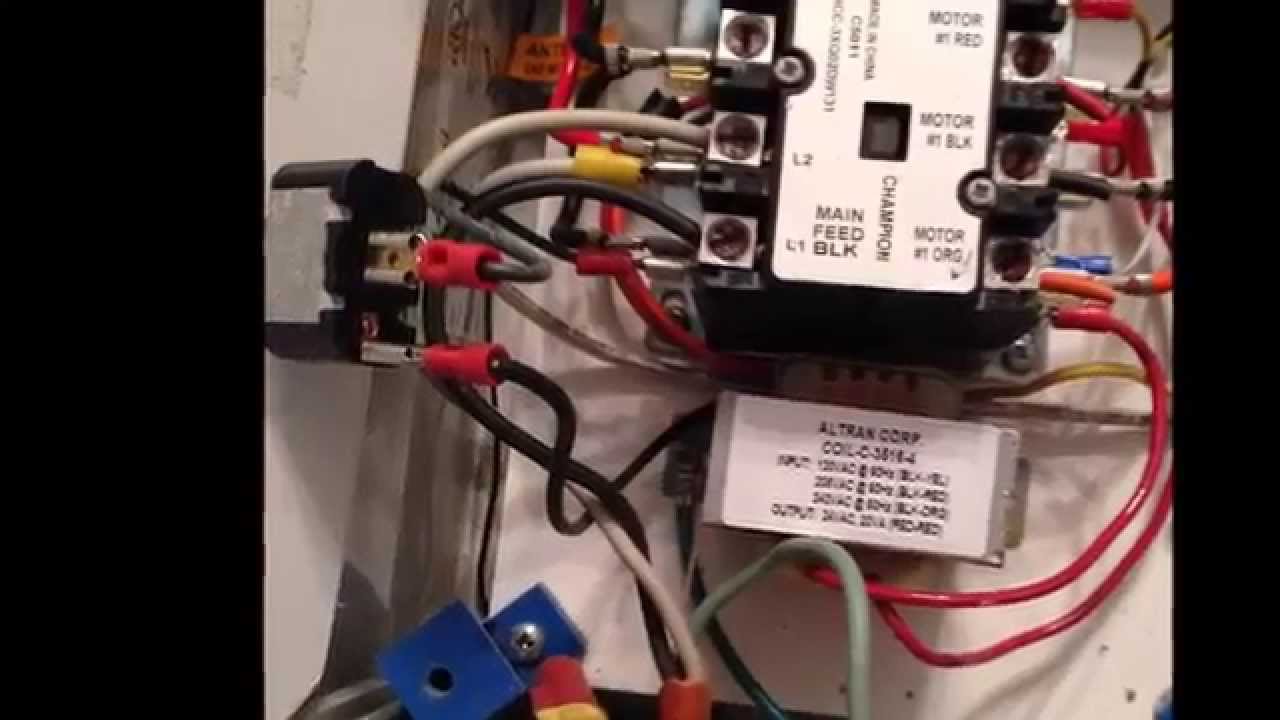

A gem lift controller typically consists of a power supply, motor control circuitry, safety features like limit switches and emergency stops, and an interface for user input. This interface can range from simple buttons to more complex touchscreens or programmable logic controllers (PLCs), depending on the sophistication of the system.

One key benefit of using a specialized gem lift control box is the enhanced level of precision it offers. These units allow for fine-tuned adjustments, crucial when handling delicate gems. For example, a jeweler might use a lift to precisely position a stone for setting. Another benefit is improved safety. Features like overload protection and emergency stops prevent accidents and protect valuable materials. Lastly, these systems enhance efficiency by automating lifting tasks, reducing manual labor and increasing throughput.

Before operating a gem lift, ensure it's properly installed and calibrated. Inspect all components for damage and verify the power supply is correct. Familiarize yourself with the controls and safety procedures before lifting any valuable items.

Advantages and Disadvantages of Gem Lift Control Boxes

| Advantages | Disadvantages |

|---|---|

| Precise control over lifting operations | Can be complex to troubleshoot |

| Enhanced safety features | Requires specialized knowledge for maintenance |

| Increased efficiency and productivity | Initial investment can be high |

Best practices include regular maintenance, operator training, and adherence to safety protocols. Keeping the control box clean and free from dust and debris is also essential.

Real-world examples of gem lift control boxes in action include diamond cutting facilities, museum exhibits showcasing precious artifacts, and jewelry workshops where intricate settings are created.

Common challenges include power fluctuations, component wear and tear, and software glitches. Solutions involve surge protectors, preventative maintenance, and software updates.

Frequently Asked Questions (FAQs) about gem lift control boxes typically cover topics such as troubleshooting common issues, safety procedures, maintenance schedules, and compatibility with different lifting mechanisms.

Tips and tricks for maintaining a gem lift control box include regularly checking connections, lubricating moving parts, and ensuring proper ventilation to prevent overheating.

In conclusion, the gem lift control box is an essential component in numerous industries, ensuring the safe and efficient movement of valuable materials. From facilitating precise gem setting to enabling the display of priceless artifacts, these units play a crucial role. By understanding their function, benefits, and best practices, users can maximize their effectiveness and longevity. Invest in proper maintenance and training to fully unlock the potential of your gem lift control system and ensure the continued safe handling of your precious cargo. Whether you’re a jeweler working with delicate stones or a museum curator handling historical artifacts, the gem lift control box is an invaluable tool for precision, safety, and efficiency. Take the time to explore the different options available and choose the system that best fits your specific needs. The future of material handling relies on innovative solutions like the gem lift control box, continuing to push the boundaries of precision and control.

Upgrade your curb appeal with a deep crimson entryway

Elk falls trail map campbell rivers hidden gem

Conquering the mold monster reclaiming your boat seats